The Cost of Farming – Hand Tools and Mechanization

Prior to the arrival of the railroad, McLean County farmers had few equipment options. Most were hand tools.

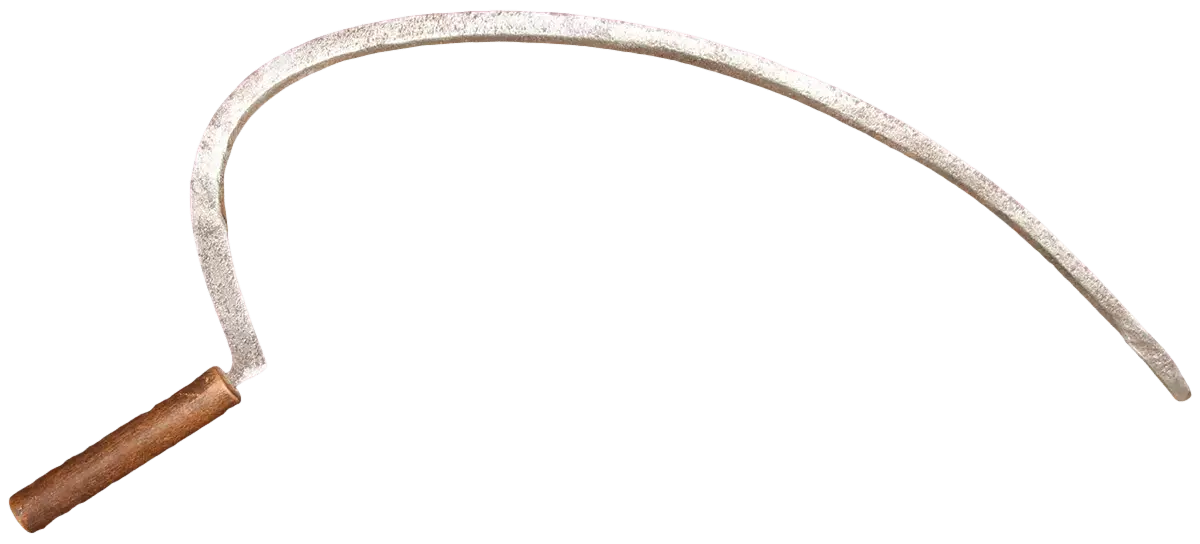

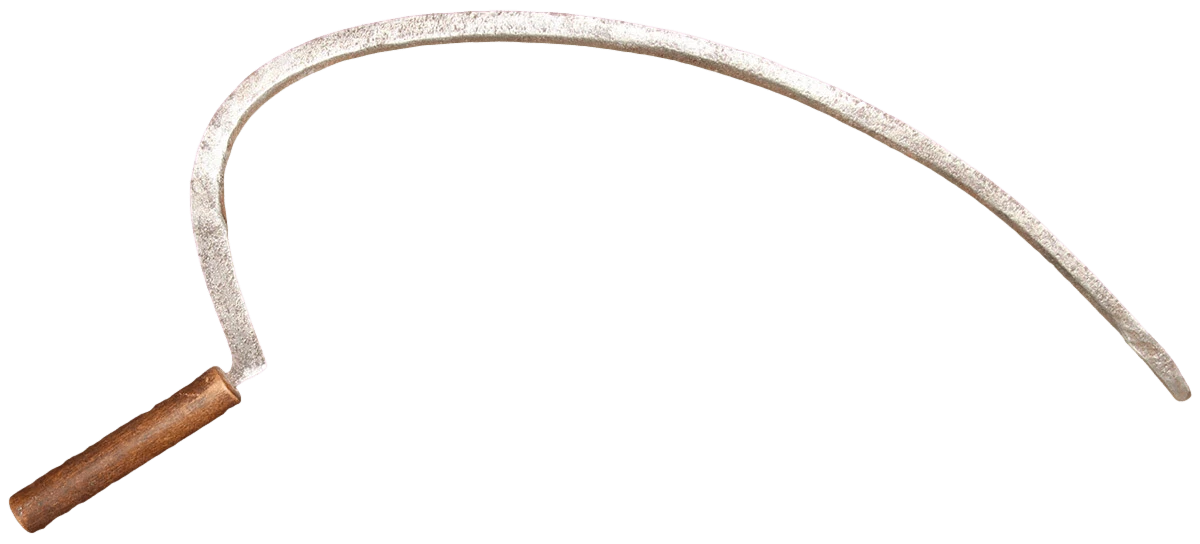

Hand corn planter, circa 1870

McLean County farmer William W. Fowler made his own hand corn planter based on one of the many developed after 1850.

The device eliminated the need to bend over, and conveniently dispensed one or more seeds into the soil. Fowler passed it onto his grandson William H. Brown, who used it for many years on his Heyworth farm.

Donated by: Walter Brown

795.243

What did it cost?

$6.89

Cost in 1870$137

Equivalent cost in 2021

Wooden hay fork, circa 1850

View this object in Matterport

Cut, raked, and dried in the field, hay was then gathered up with a pitch fork and stored in mounds in the field, or moved by wagon to the barn loft until needed. This crop supplemented pasture and other grain fed to work animals and livestock.

Donated by: Grover Katthoeffer

725.34

What did it cost?

$1.09

Cost in 1850$36

Equivalent cost in 2021

Hand Tools

Set in their ways or unable to afford mechanical cutting and binding equipment, some farmers continued to use hand tools well into the 1930s.

Frontier farmers put their entire family to work, as hand-harvesting grain crops was labor intensive.

According to Simon Moon, who farmed the John Gregory farms south of Gridley and west of Lexington, it took about 15 hours to pick and husk an acre of corn. If Moon had 120 acres of corn, how long would it take him to pick and husk his corn?

New Tools

The availability of new tools increased dramatically after the railroad arrived. With raw materials also arriving by rail, local entrepreneurs began manufacturing equipment. By the end of the 19th century most farm tools had been mechanized.

Riding Corn Planter

In 1855 a new riding corn planter arrived from Galesburg.

Pulled behind a horse, Brown’s Corn Planter had a seat for the farmer who drove the team of horses, and a seat for a second rider who triggered the release of the corn seed into the ground.

Forty inches was the typical distance between the seed hills and each row. This distance allowed room for the horse and meant that the growing corn could be cross cultivated in several directions without being damaged.

add cost

What did it cost?

$65

Cost in 1855$2,294

Equivalent cost in 2023Check-row Attachments

By the 1870s check-row attachments had been developed for two-row corn planters. The devices were designed to drop corn seed at equal distances in checkerboard fashion. This allowed for cross cultivation.

What did it cost?

$33

Cost in 1877$965

Equivalent cost in 2023Two-row horse drawn riding cultivators arrived via the railroad as well.

McLean County farmers worked hard to keep weeds under control. Riding cultivators made the job easier, but farmers still had to walk through their fields to hand hoe weeds missed by the cultivator.

What did it cost?

$22.50

Cost in 1856$813

Equivalent cost in 2023C.W. Holder & Company

In the 1850s and 60s C.W. Holder & Company was a primary supplier to McLean County farmers. This Bloomington business sold both new innovations and standard equipment brought in by rail.

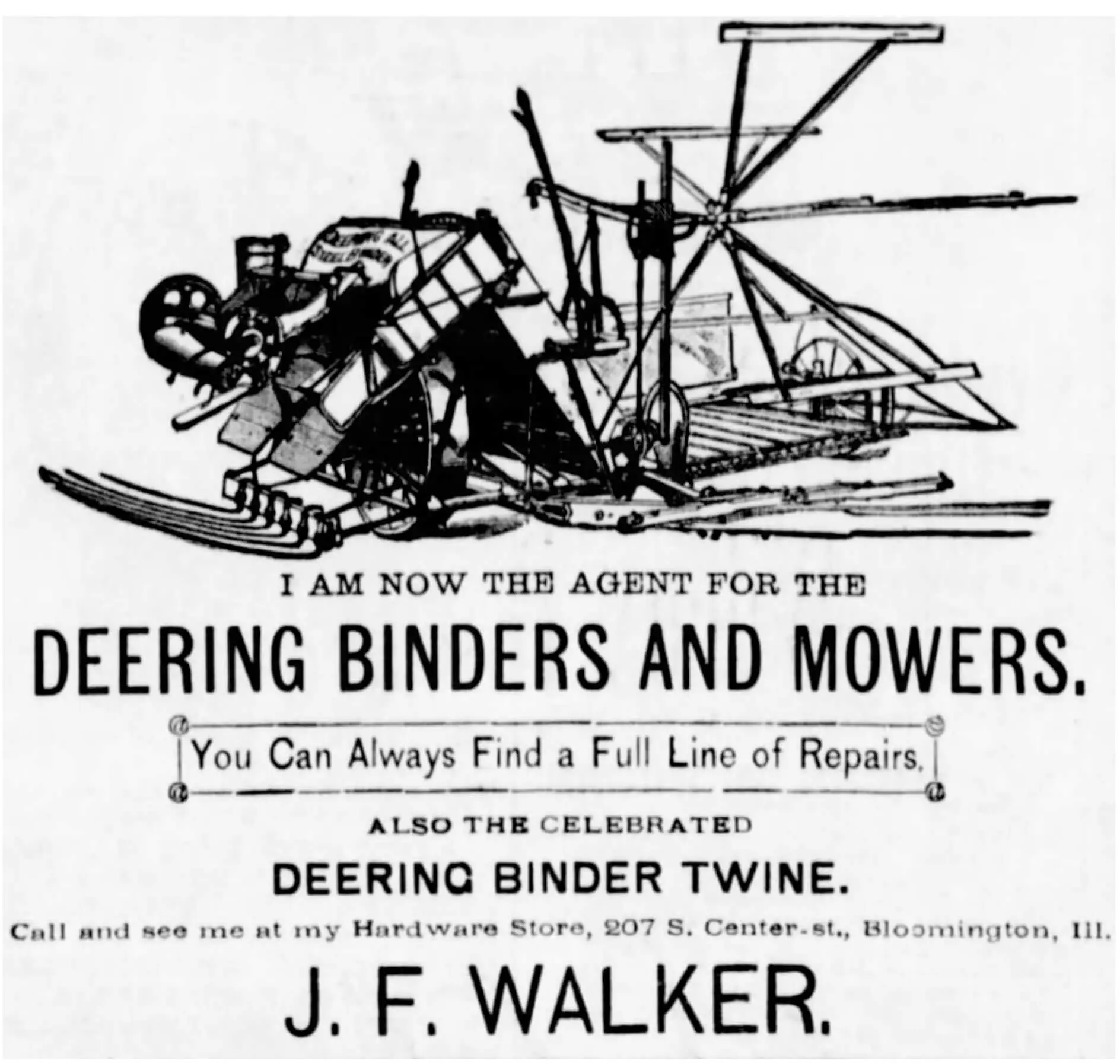

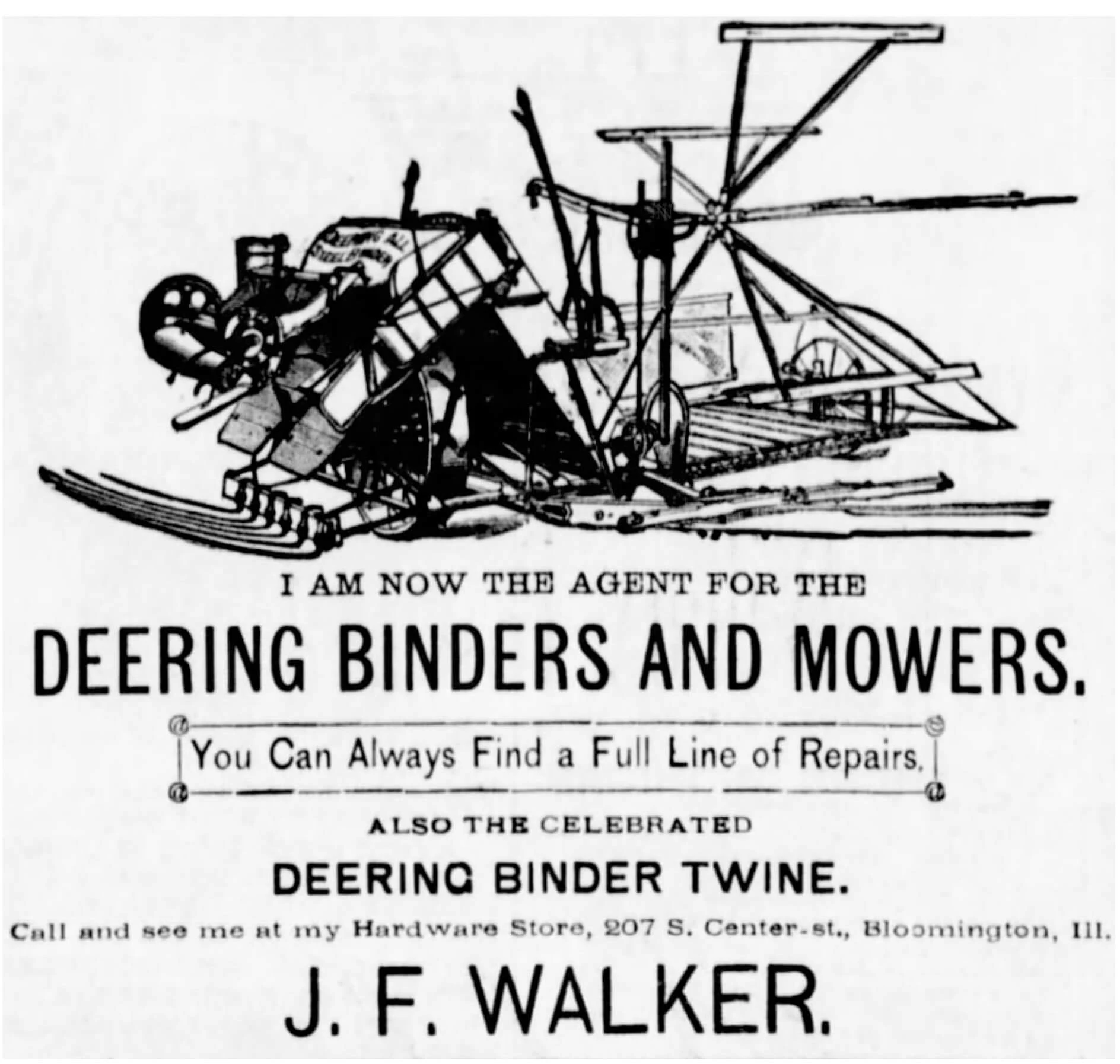

New and improved binders and mowers for cutting hay and small grains soon arrived via the railroad. Though expensive, they reduced the amount of time it took to complete these tasks and saved the farmer both the time and money he would have spent for hand labor.

What did it cost?

$183

Cost in 1886$5,977

Equivalent cost in 2023Horse Drawn Corn Cutters

Innovative horse drawn (or pushed) corn cutters with binders dramatically reduced the human labor needed to complete these tasks.

Former Hudson farmer turned equipment salesman, C. H. Salzman, demonstrated the Osborne horse drawn corn cutting and binding machine at the Hudson farm of M. Troyer in 1889.

The cost to hire someone to cut and shock corn has reached seven cents per shock, making it very expensive feed for the ordinary stockman or farmer. More cattle can now profitably be kept than before the invention and perfection of this machine.

C.H. Salzman

Bloomington Pantagraph, August 24, 1889

What did it cost?

$121

Cost in 1890$4,082

Equivalent cost in 2023“Big Injun” Sulky Plow

In 1888 L.L. Crawford purchased a “Big Injun” sulky plow from Bloomington’s Hyde & Martens Company.

He had much to say about the use of this plow:

"I am well pleased with the working of the Big Injun Sulky Plow... Went into a slough that had never been plowed, and with three horses turned it upside down in a splendid shape. Have tried seven different plows that same place, using as high as six horses... Never saw a plow that run so nicely and handled so well."

L.L. Crawford, McLean, Illinois

Bloomington Pantagraph, September 6, 1888

What did it cost?

$41

Cost in 1888$1,325

Equivalent cost in 2023Threshing Equipment

Hand and horse powered threshing equipment reduced the labor needed to separate grains, such as wheat and oats, from their stalks and husks. But by the late 19th century steam powered engines were used to power threshing machines.

Steam engines, based on the same technology as railroad engines that used wood and coal as fuel, dramatically reduced the labor needed to power threshing machines, like the one pictured here. The engine was parked and the crop was brought from the field to the threshing machine, which was powered with a belt by the engine.

What did it cost?

$20

Cost in 1900$731

Equivalent cost in 2023Alternative Power Sources

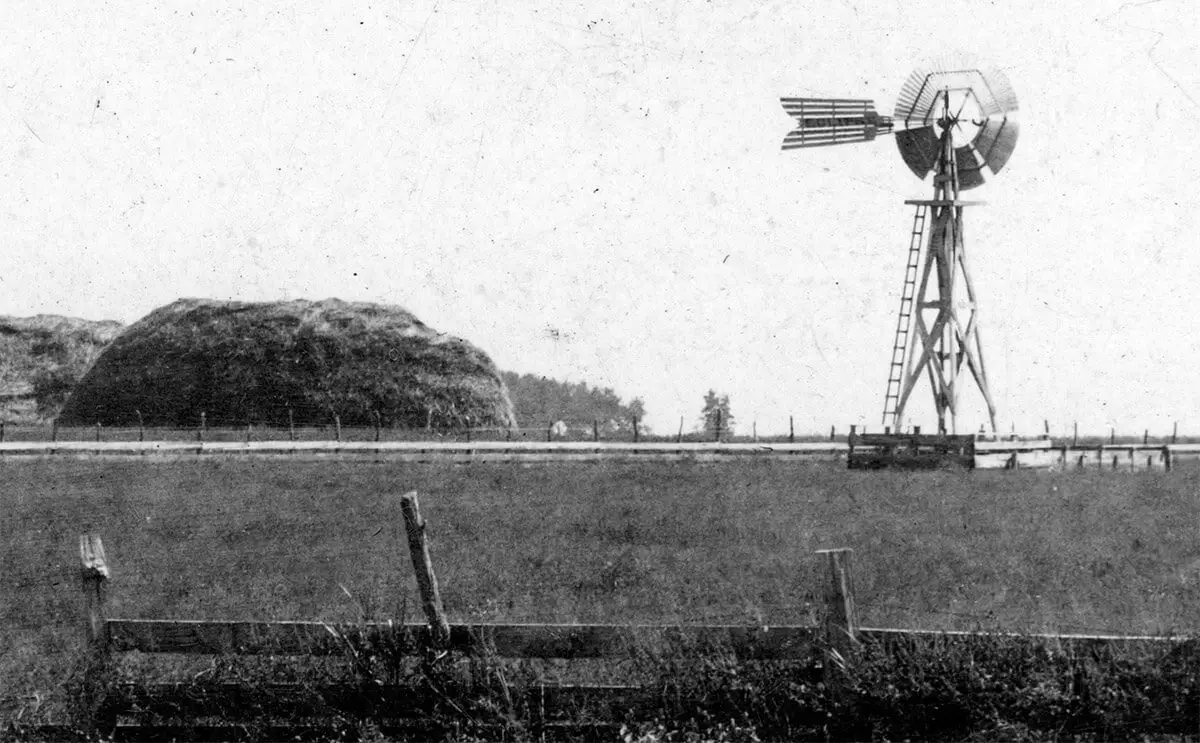

With no electricity on most McLean County farms until the late 1930s, some farmers invested in alternative power sources.

Around 1880 Colfax farmer Thomas Kilgore installed a windmill to power the pump that brought water from a well for his livestock.

In the early 20th century, most McLean County farmers had grinding wheels for sharpening tools and a hand corn sheller for removing corn kernels from the ear.

These were both used on the Louis Giese farm near Shirley and were believed to have been purchased from J. P. Walter’s hardware store in Shirley.

Giese used the sheller to hand shell the corn he fed his livestock.

Want to see more late 19th and early 20th century farming equipment?

Visit the Funk Prairie Home and Mineral Museum just off Interstate 55 near Shirley, Illinois.

Making a Home

Making a Home

A Community in Conflict

A Community in Conflict

Working for a Living

Working for a Living

Farming in the Great Corn Belt

Farming in the Great Corn Belt

Abraham Lincoln in McLean County

Abraham Lincoln in McLean County