Craftsmen

Blacksmiths, tinsmiths, and brick-makers possessed skills helpful for survival when Euro-American began to settle this area. If the materials they needed to practice their crafts were not available locally, it was expensive but necessary to transport them by boat to Pekin, and then by wagon to Blooming Grove.Featuring:William Richard Goodheart, (1770 – 1842), brickmakerLewis Bunn, (1806 – 1886), BlacksmithGeorge Dietrich, (1816 – 1900), TinsmithScottish immigrant William Richard Goodheart (1770-1842) arrived in Blooming Grove in 1825. He built his family a log home using resources from the land.

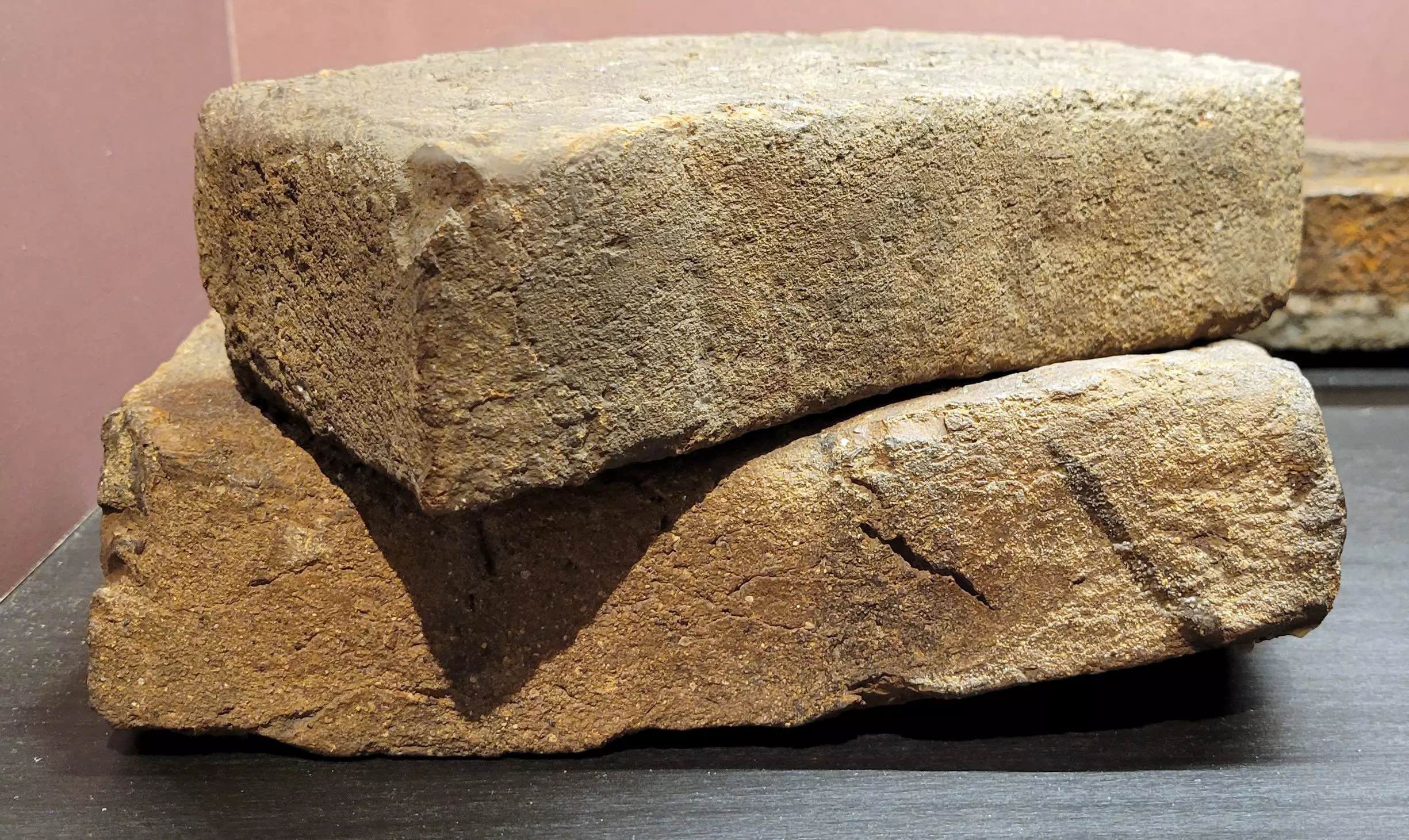

Log homes required a fireplace for heating and cooking. Those living on the frontier used the materials available to them (rocks, clay, logs, and sticks) to construct the chimneys for their homes. But William did it differently.

Using clay from his farm, William manufactured the first bricks in McLean County and used these bricks to construct the chimney of his new home.

William’s neighbors soon asked him to make more bricks, which they purchased to build brick chimneys for their homes.

Ohio native Lewis Bunn (1806–1886) was Bloomington’s first trained blacksmith, having moved to Bloomington in 1833.

The iron Lewis needed to make horseshoes and plows was not available on the frontier, so he ordered iron from St. Louis to be shipped by flatboat to Pekin via the Mississippi and Illinois rivers.

With supplies ready and his forge set up, Lewis heated, hammered, and shaped the metal into iron plows, hoes, and other agricultural implements. He made horseshoes, mended broken tools, and fashioned hooks, hinges, and other metal hardware, which he sold to other settlers.

Demand for Lewis’ work was high as his closest competition was 40 miles away. He named his price, charging $11 to $12 for a plow. When a second blacksmith, Oliver Ellsworth, arrived in 1836, Lewis had to offer competitive prices or risk going out of business.

But competition was not Lewis’ only challenge. When an 1837 financial crisis reduced the amount of cash on the frontier, many customers could not repay the credit he had given them, and he lost money.

At that time Lewis stopped giving customers credit and reduced his prices.

George Dietrich (1816-1900) came to McLean County in 1839, having trained as a tinsmith in New Jersey.

When he arrived he found no competition, just a failed business from which he bought additional tools and supplies. He was soon at work hand-fabricating needed household items like buckets, lanterns, candle molds, and candle holders, for which there was a growing demand.

Dietrich used tools, like hand forged shears and a soldering iron, to make tin grease lamps and candle molds in his shop.

Dietrich’s records show he traded his products for meat, buggy and sleigh rides, home repair, wood flooring, and firewood.

More tinsmiths arrived with the railroad. In 1855 there were four other tinsmiths in town. In 1857 Dietrich sold his business and left town.

Making a Home

Making a Home

A Community in Conflict

A Community in Conflict

Working for a Living

Working for a Living

Farming in the Great Corn Belt

Farming in the Great Corn Belt

Abraham Lincoln in McLean County

Abraham Lincoln in McLean County