Today’s larger wind farms can include hundreds of 280-feet tall turbines and cover thousands of acres, generating enough megawatts to power all the homes in the Twin Cities and more.

Although generating electricity on this scale is a modern day triumph, harnessing the prairie wind goes back a long way. Before the sleek, modern behemoths of the 21st century there were the much smaller, water-pumping windmills of the 19th century.

These older windmills, roughly averaging some 40 feet in height, were well-engineered machines, favored by farmers for their ingenious practicality. They also drew admirers from afar, offering as they do a striking vertical presence in a horizontal world.

It’s been more than a century since the heyday of the old water-pumping windmill, though survivors, many in various stages of neglect, can still be seen scattered hither and yon throughout Central Illinois.

The first such windmills were developed in the mid-1850s by Connecticut machinist Daniel Halladay. They differed dramatically, both in form and function, from traditional European windmills (think Don Quixote) built and operated to mill grain—hence the “mill” in windmill. In contrast, American windmills, often called wind engines, were used almost exclusively to pump water from groundwater wells for livestock and household needs.

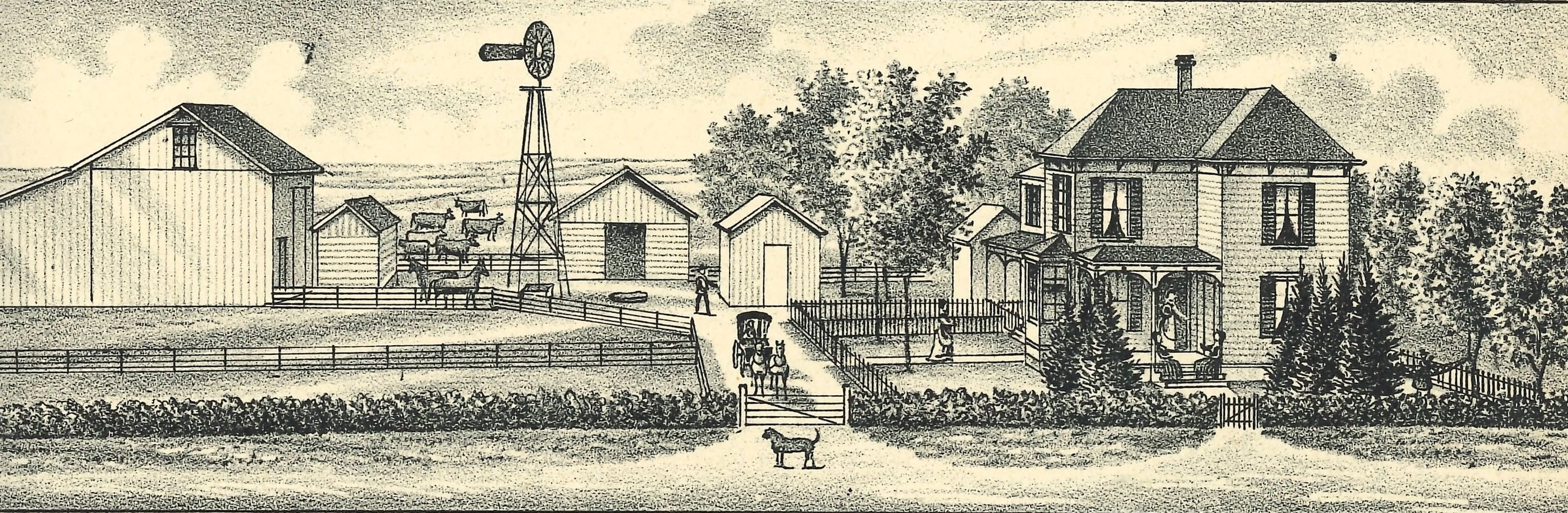

The golden age for water-pumping windmills on the Corn Belt stretched from the 1880s into the 1920s. One can track the early rise of these “wind pumps” in McLean County by examining two 19th century sources. Of the 50-plus detailed lithographic illustrations of farmsteads in the 1874 Atlas of McLean County, only two feature windmills. Yet thirteen years later, in the 1887 Portrait and Biographical Album of McLean County (see accompanying image), windmills are visible in about 25 of the some 85 farm illustrations.

The American windmill is a relatively simple yet elegant machine. Most feature a light tower frame (or derrick) of four sloping legs. The fan, usually comprised of curved steel blades in a rosette pattern, sits on a platform atop this tower.

Unlike its Old World counterparts, the American or “prairie” windmill is self-governing. This means the fan automatically rotates with favorable shifts in wind. The rotating blades and their maximum speed are also kept in check to prevent the whole mechanism from being shaken apart by centrifugal forces during extremely high winds.

A gearbox and crankshaft convert the rotary motion of the fan into reciprocating vertical strokes of a pumping rod, which runs the length of the tower down to the terra firma and the groundwater well.

Early windmills had open gearboxes that required farmers to scale their towers every few days to lubricate the contact points, a laborious and dangerous chore that led to a fair number of serious accidents and more than a few fatal falls. The development of enclosed or “self-oiling” gearboxes, in which the moving parts were bathed in light lubricating oil, was a major timesaver and safety improvement, for they required servicing but once or twice a year.

Illinois was a major state for windmill manufacturing, with Batavia as the undisputed center. Windmill inventor Daniel Halladay’s company, the U.S. Wind Engine & Pump Co., relocated from New England to Batavia in order to be closer to its emerging markets in the Corn Belt and Great Plains. Batavia, straddling DuPage and Kane counties west of Chicago, would earn the nickname “Windmill City.”

Windmills were first constructed of wood. The use of galvanized steel, which came into widespread use in the 1890s, revolutionized the industry.

In the early 20th century, Palmer-Darnall Co., 209-211 E. Front St. in downtown Bloomington, acted as a dealer for Chicago-based Aermotor Windmill Co., one of the nation’s leading manufacturers (Aermotor still makes windmills, though the company is now based in San Angelo, Tex.) And in the summer of 1902, Charles A. Downs, as travelling agent for the U.S. Wind Engine & Pump Co., set up shop at a downtown Bloomington hotel to take orders for immediate delivery. Downs advertised several of the company’s windmill models, including the Halladay, Comet, Gem and Standard.

The coming obsolesce of the windmill on the Corn Belt can be glimpsed in an advertisement for gasoline-powered pumps in the March 1, 1911 Farmers Voice, a Bloomington-based weekly. “The farm pump engine is fast supplanting windmills in every part of the country,” declared Fuller & Johnson Mfg. Co. of Madison, Wis. Unlike windmills, dependent as they are on the vagaries of Mother Nature, the farm pump could operate 365 days a year. Fuller & Johnson asked farmers to consider purchasing “such an engine for less than the cost of an unreliable, lazy, rickety, dangerous windmill!”

The death knell for the windmill came in the form of the Rural Electric Act, which in the late 1930s brought electricity to Corn Belt farms. And with electricity came not only electric lights but electric pumps, which soon supplanted windmills as the power source of choice for farmers needing to pull groundwater up to the surface.

A 1969 survey of the rural McLean County landscape identified 304 standing windmills, though not a single one was in operation. Even so, as testament to their simplicity of form and sound engineering, “the general condition [of many] was surprisingly good.” At the time, a few had even been repurposed as television antennas.

Windmills are still manufactured in the American Southwest, where they are used by mainly by remote livestock operators pumping water and aerating ponds.

There are those with an interest in preserving and restoring Midwestern windmills. Paul Behrends of rural Foosland, a village in Champaign County, operates Paul’s Windmill & Crane Service. Behrends, whose great uncle was an executive vice president of Aermotor Windmill Co., is a “full-time windmiller,” having sold, serviced and installed them throughout the Midwest for a quarter century.

On April 6, 1858, Abraham Lincoln debuted a curious lecture he called “Discoveries and Inventions” at Centre Hall in Bloomington (a year later, poor attendance led to the cancellation of a repeat performance!)

In this lecture, Lincoln’s observations of, and speculations on, wind power, though far from novel, were certainly prescient. “Of all the forces of nature, I should think the wind contains the largest amount of motive power—that is, power to move things,” he declared. Yet apart from sailing vessels and a “few windmills, and pumps … no very successful mode of controlling, and directing the wind, has been discovered.”

Concluded Lincoln: “The wind is an untamed, and unharnessed force; and quite possibly one of the greatest discoveries hereafter to be made, will be the taming, and harnessing of the wind.”